73 water 5 - 6 bentonite 21 - 22 cement by weight RE. When mixing on site its imperative to get the water volume with cement powder content right.

The Feasibility Constructability And Efficacy Of Tire Derived Aggregate As A Component In Slurry Cutoff Walls Ppt Video Online Download

Tolunay-Wong hydrated the bentonite slurry for 4 hours prior to adding it to the soil or to the soil and dry bentonite mixtures.

. Slurry Cutoff Wall Design Parameters. The viscosity of the mixed slurry is designed to be in the fluid range during the excavation process. Step 2 starts agitation vat.

Cement shall be added to the bentonite slurry just before introduction in the trench. Day ÄBSTRÄCT Ä cementbentonite CB slurry cutoff wall is a variation of the slurry wall process that is used to create an underground barrier to stop the lateral flow of ground water and other fluids. INTRODUCTION If the natural soil does not meet the requirements of the.

Cubes and cylinders were casted with M30 design mix and compressive split tensile. 100 69-72 6-12 Self-hardening slurry Impermix. Weldon Concrete has 3 modern plants and over 35 mixer trucks that service North Central New Jersey and can produce up to 2000 yards of concrete per day.

Bentonite slurry shall be prepared by mixing water and bentonite until the bentonite particles are fully hydrated and the resulting slurry appears homogeneous. The lower the bentonite extended cement slurry density is cement mechanical properties will be poor Table 3-3 and 3-4 taken from Well cementing II edition and The addition of bentonite to a cement slurry requires additional mix water. Depending on workload experience availability of quality cement and.

This combination is frequently utilized to form a solid protective barrier in the ground. Bentonite can be added to any API class of cement and is commonly used in conjunction with other extenders. Once the excavation is to full depth the bottom is cleaned and the process moves on.

The mixture including 10 bentonite 90 sand is the most economical solution that satisfies the limits values needed for clay core of earth fill dams and clay liners of solid waste storage areas. Pump Pump Type 316 progressing cavity OutputPressure variable up to 20 gpm 261 psi Colloidal Mixer Mix Tank 130 CF with bottom clean out Mixing Pump 2 x 3 x 6 diffuser- type. Airfields and heavy-duty concrete pavement less than 10000 cubic yards.

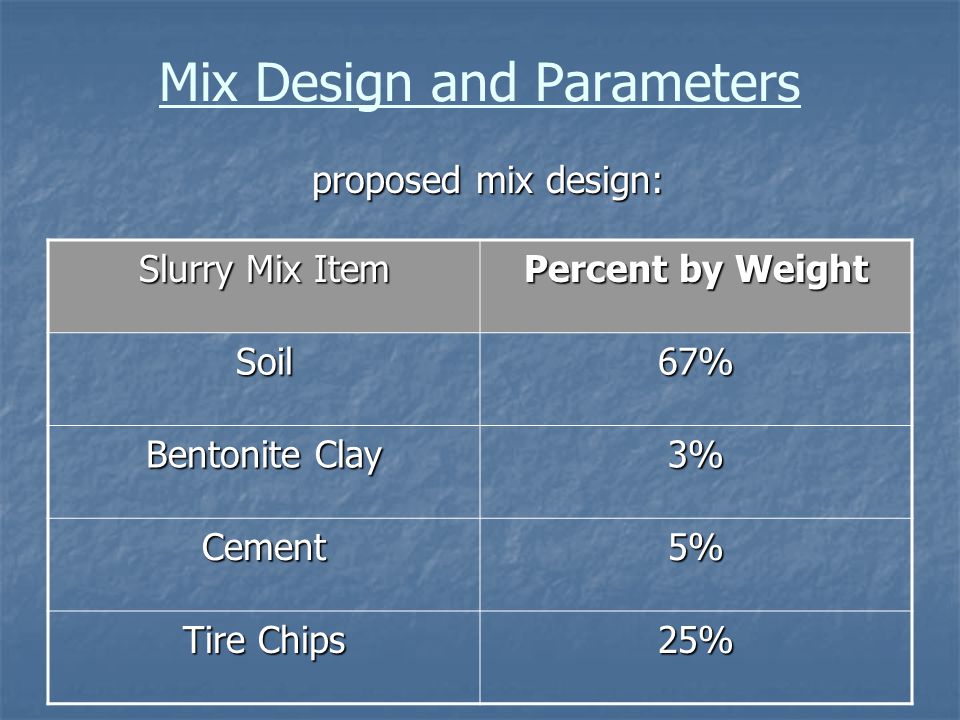

100 69-72 8-16 Self-hardening slurry Composite wLiner. Bentonite slurry shall be prepared by mixing water and bentonite until the bentonite particles are fully hydrated and the resulting slurry appears homogeneous. The final mix design consisted of 180 pounds of cement 51 pounds of flyash 2542 pounds of soil dry weight 50 gallons of bentonite slurry and 312 gallons of reservoir water.

Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. This minimizes the slurry seepage out of the trench and groundwater seepage into the trench. A rule of thumb is for each 1 of bentonite an additional 53 of water is required.

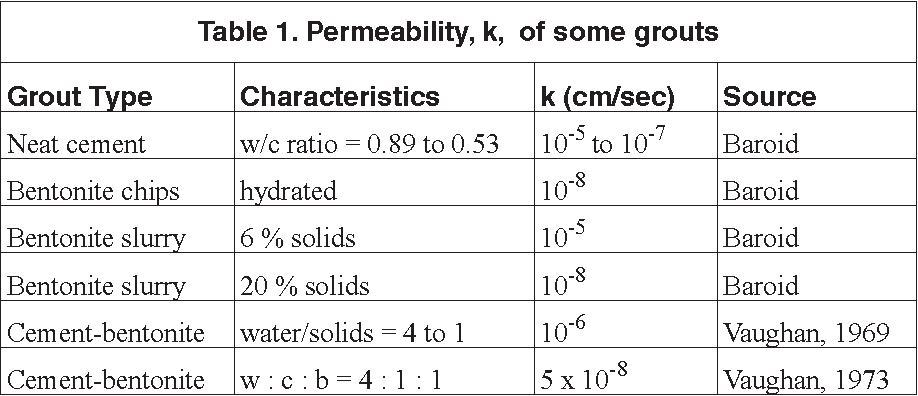

Design Proportions For Sccb Mix Design Program Download Scientific Diagram At the slurry plant cement or some other setting agent is added to the bentonite slurry. Soil-Cement-Bentonite SCB slurry walls have been used with increasing frequency in recent years to provide barriers to the lateral flow of groundwater in situations where the strength of a normal soil-bentonite wall would be inadequate to carry foundation loads. 1 x 10-10 NA NA 7-14 Depth Limitations.

If the concentration Cs is expressed as kilograms of bentonite per cubic meter of final slurry then the formula becomes. Step one adds the water choosing ratio mass fraction in agitation vat. Start Your Project Sooner with Store Pickup.

In addition to these design standards designers shall integrate sound engineering judgment applicable national codes and design standards site-specific technical considerations and. Soil-Bentonite Slurry Trench Cutoff Wall Longevity. The C-B slurry coats the sides of the trench with a thin slippery layer known as a filter cake.

CEMENT-BENTONITE SLURRY WALL MIX DESIGN Christopher R. The soil bentonite slurry wall is part of the IWWTP Work at Gulf Power Company Plant Scholz in Sneads Florida. Source water was poured into the mixer and the mixing blade was turned on then bentonite was added.

Bentonite cement earthfill sand unpermeable layer. Weldon Concretes technical marketing and operations people supply contractors and masons with the highest quality mixes whether they be for a sidewalk pool structure or a Port Authority. Mix Design Rules In order to keep field procedures simple the emphasis.

1 x 10-6 25 70-75 6-12 Self-hardening slurry. Because of the relative simplicity. Composite Slurry Wall and Liner.

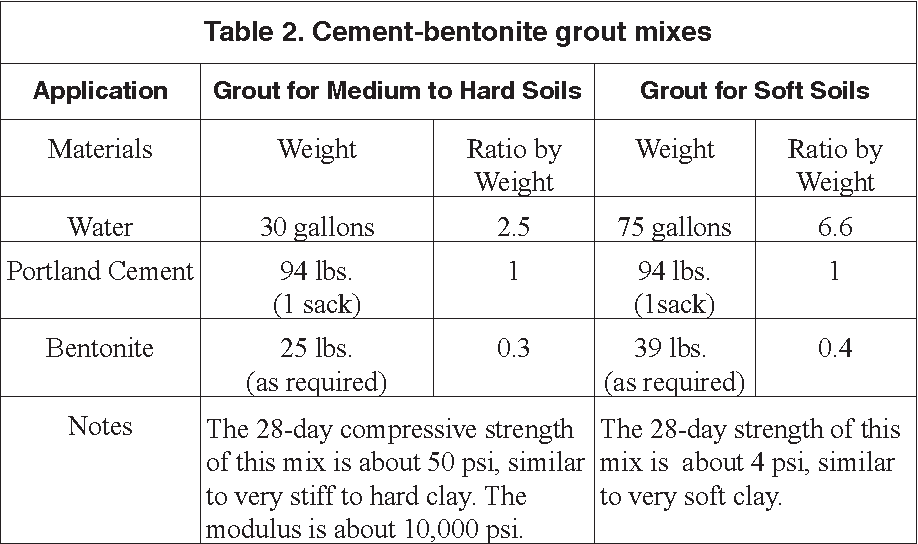

Ad Shop Concrete Cement Stucco Mix Today Get Great Deals On Quality Products. Cement-bentonite slurry walls also provide another alternative. The slurry is then pumped from the mix plant to the excavation.

Ps pw 1 C CGp 1 where pw is the specific gravity of the mixing water assumed to be 10 and Gp is the grain specific gravity of the bentonite powder used to prepare the slurry. Step 3 adds cement wilkinite soda ash in agitation vat successively in the mass fraction choosing ratio and stirs. Download article as PDF.

Slag cement-Bentonite 5 x 10-7. Facebook Twitter LinkedIn Email. A preparation method for cement bentonite slurry body preparation comprises the following steps.

Most specifications allow for a maximum of 6 gallons of water per 94 pounds. The bentonite slurry was mixed in a Hobart mixer. The C-B slurry is prepared by combining cement with a hydrated bentonite-water mixture just before discharge of the C-B slurry into the trench.

A slurry is a thin sloppy mud or cement or in extended use any fluid mixture of a pulverized solid with water often used as a convenient way of handling solids in bulk. Bentonite slurry is a combination of sodium bentonite and slurry. 6 rows bentonite powder.

Find the Right Material For Every Job. The flowchart below is a simple point of departure to design conventional cement slurry systems for each well-cementing laboratory. 5 x 10-7 50 95-120 5-10 Typically remote mix.

Evaluation of Cement Bentonite Slurry Wall Mix Design. Storage ponds may be used to hydrate the bentonite slurry. Typically 21 ratio BentoniteCement.

R an Steven R. At the slurry plant cement or some other setting agent is added to the bentonite slurry. The bentonite slurry was mixed for a period of three minutes.

Data are presented from design mix studies and field-testing programs to. The cement slurry mix design formulation would strongly depend on the experience of the laboratory itself database and the lab technician.

Sb Slurry Trench Cutoff Wall Schematic Lagrega Et Al 2010 Download Scientific Diagram

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Blend Mix Proportions And Blend Slurry Properties Download Table

Concrete Mix Design Used For Laboratory Tests Download Table

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved

0 comments

Post a Comment